- Avia

- Astra

- AEC

- Allison Transmission

- Austin

- AGCO

- Allis Chalners

- Albion

- AMW

- BAW

- Beifang Benchi

- Bedford

- Case IH

- Caterpillar

- Cummins

- Claas

- Citroen

- Challenger

- DAF

- Daihatsu

- Daewoo

- Deutz

- Doosan

- Dodge

- DongFeng

- Detroit Diesel

- Duramax

- Eaton

- FAW

- Fendt

- Ferguson

- Freightliner

- FiatAgri

- Ford

- Fordson

- Hania

- Hino

- Hyundai

- Howo

- Iveco

- International

- ISUZU

- JAC

- JCB

- John Deere

- Kia

- Kenworth

- Kubota

- Komatsu

- MAN

- Mack

- Marmon-Herrington

- Mercedes-Benz

- Mitsubishi

- Nissan

- Paccar

- Perkins

- Peterbilt

- Renault

- Scania

- Shaanxi

- TATA

- Tadano

- TEREX

- Tatra

- UAZ

- URAL

- Valtra

- Versatile

- Volvo

- Wechai Power

- Western Star

- XCMG

- Yanmar

- Yuchai

- Yuejin

- ZIL

- Zoomlion

- Forklift

- ACE

- Agrison

- Armanni

- Atlet

- Balkancar

- Baoli

- Bendi

- Big Joe

- BT

- BYD

- Carer

- Case

- Caterpillar

- Cesab

- Chery

- CHL

- Cholift

- Clark

- Crown

- Daewoo

- Dalian

- Doosan

- Drexel

- Eurolifter

- Feeler

- Gros

- Hangcha

- HanseLifter

- Heli

- Hyundai

- JAC

- JCB

- JLG

- John Deere

- Jungheinrich

- Kalmar

- Komatsu

- Lonking

- Linde

- Manitou

- Mariotti

- Mitsubishi

- Nichiyu

- Nissan

- Noblelift

- OMG

- Pettibone

- Raymond

- Rocla

- Shantui

- Taylor

- Toyota

- TCM

- Terex

- UniCarriers

- UN

- Voltas

- XGMA

- XCMG

- Yale

- Zoomlion

- Avia

- Astra

- AEC

- Allison Transmission

- Austin

- AGCO

- Allis Chalners

- Albion

- AMW

- BAW

- Beifang Benchi

- Bedford

- Case IH

- Caterpillar

- Cummins

- Claas

- Citroen

- Challenger

- DAF

- Daihatsu

- Daewoo

- Deutz

- Doosan

- Dodge

- DongFeng

- Detroit Diesel

- Duramax

- Eaton

- FAW

- Fendt

- Ferguson

- Freightliner

- FiatAgri

- Ford

- Fordson

- Hania

- Hino

- Hyundai

- Howo

- Iveco

- International

- ISUZU

- JAC

- JCB

- John Deere

- Kia

- Kenworth

- Kubota

- Komatsu

- MAN

- Mack

- Marmon-Herrington

- Mercedes-Benz

- Mitsubishi

- Nissan

- Paccar

- Perkins

- Peterbilt

- Renault

- Scania

- Shaanxi

- TATA

- Tadano

- TEREX

- Tatra

- UAZ

- URAL

- Valtra

- Versatile

- Volvo

- Wechai Power

- Western Star

- XCMG

- Yanmar

- Yuchai

- Yuejin

- ZIL

- Zoomlion

- Forklift

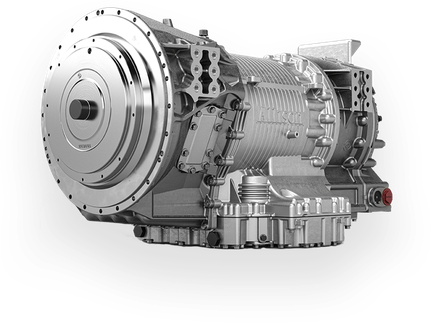

Allison Transmission Service Manuals

Allison Transmission

That is how long Allison has been around. Throughout its long history, Allison products from the United States were known both in motorsport and in aviation, but in our century, its main activity is the production of automatic gearboxes and hydraulic drives. The transmission with the Allison Transmission logo can be seen on a dump truck, fire truck, shuttle bus, main tractor, and even on an all-wheel drive army truck, tank, self-propelled construction, road and agricultural equipment.

The headquarters of the company is located in Indianapolis (USA), and the main production facilities are located, in addition to the United States, in Brazil, India, China, and since 2011 a plant has been launched in Hungary. The production range of this assembly site includes automatic gearboxes of the 3000, 4000 and Torqmatic series for the company's customers, including almost all brands known in the automotive world.

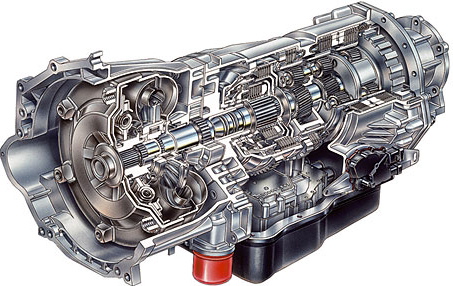

The 3000 series transmission for medium-duty commercial vehicles is a classic 6-speed hydromechanical gearbox with programmable electronic control, working with engines of up to 336 kW and a torque of up to 1695 Nm. This unit weighs, depending on the configuration, from 243 to 297 kg. The 4000 series for heavy equipment can have 6 or 7 stages and can handle power up to 597 kW and torque up to 2644 Nm, the weight of the 4000 series gearbox is up to 555 kg. These gearboxes can be combined with additional options (retarder, power take-off) to expand the range of applications. Gearboxes of the Torqmatic family are designed for passenger buses, have 6 gears, an integrated retarder and work with motors with a power of up to 410 kW and a maximum torque of 2550 Nm.

The share of automatic transmissions in the US car park is about 96%, this tradition is about 80 years old, at least, and Allison Transmission introduced the world's first fully automatic transmission for commercial vehicles almost 70 years ago. What caused such a love for "automatic machines", okay, still chic American sedans and limousines, but what have heavy trucks and buses to do with it, because, as you know, the GMF is always more voracious, slower and more expensive than a simple mechanical transmission. It is on this topic that Allison Transmission experts love to discuss. Here are their reasons.

The first and very urgent worldwide problem is the qualification of the driver, but with an automatic transmission it is much easier to ensure the smooth operation of components and assemblies and thereby extend their life, moreover, errors in the selection of gears are excluded, and this contributes to fuel economy. And one more nuance. The Allison transmission can be programmed to limit speed and power to prevent traffic violations and / or increased wear.

The second is, in principle, an automatic hydromechanical transmission, the only one that provides a continuous flow of power from the engine to the drive wheels.